Aligned For Successful Application

As standard, the dry thermoplastic TecWeb® is delivered on a roll without foil or silicone paper. On customer request, delivery on a carrier is possible. TecWeb® adhesive is not a film with a closed surface, but a porous three dimensional structure. The open structure makes the resultant laminate more flexible and breathable. Due to the structure of TecWeb® adhesives, other names such as veil, non-woven, nets or fleece adhesive are common.

Flexible And Innovative

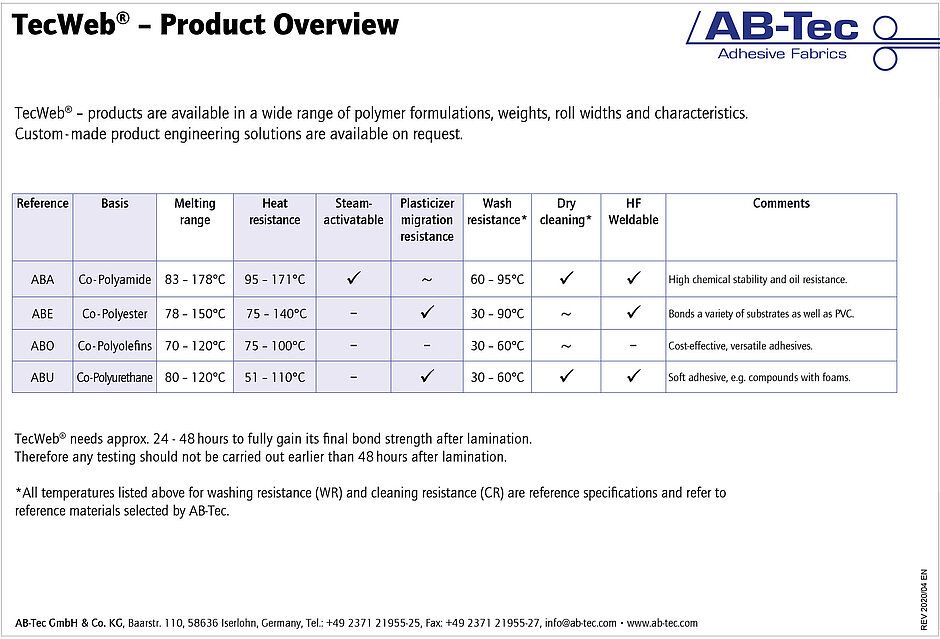

TecWeb® offers an extremely versatile pallet of High-Tech adhesives. This large flexibility results from different base polymers used to formulate the webs, e.g. co-polyamides, co-polyesters, co-polyolefins and co-polyurethanes. Webs are available in weights from 6 g to 60 g per square meter and in wide widths.

Temperature, Pressure And Time

In order to process TecWeb®, three fundamental parameters are to be considered: temperature, pressure and time. To activate the thermoplastic web adhesive, a glue line temperature above the melting point is required. Pressure and time are then coordinated with the respective substrates, in order to ensure the highest quality laminate.

Special Characteristics

- predictable performance and adhesion strength

- light weights

- open structure: does not trap air, steam- and air-permeable

- superb mechanical properties, excellent vacuum or thermoforming characteristics

- high resistance to chemicals such as lubricants, fuel and oils

- soft hand and high elasticity of flexibility

- limited penetration into porous or absorbent materials / substrates

- limited rustling noise (compared to a film or foil)

Production / Handling

- supplied in roll form

- continuous production

- easy to work with, high operating speed

- clean handling; no cleaning process necessary

- bonding of large material surfaces

- thermoplastic features

- rapid cooling

- processing and activation by flat-bed laminating, heat and pressure calendering or infra-red systems

- depending on the type of TecWeb®, steam activation and HF welding is possible

- resistance to coldness: unproblematic concerning transport and storage

Economical

- 100 % solids, no water

- environment-friendly: solvent-free and plasticizer-free

- edge to edge coverage

- precise adhesive weight on total surface

- consistent product quality, high reproducibility

- less waste (adaptable widths and weights)

TecWeb®

Product Overview

| Co-polyamides | Steam activatable, high chemical stability and oil resistance. |

Co-polyesters | Bonds a variety of fabrics and other substrates as well as PVC. |

| Co-polyolefins | Good wash characteristics; favourable price, efficient and effective. |

| Co-polyurethanes | Offers aggressive bonding to a wide range of products / substrates. |